When AI becomes an expensive toy

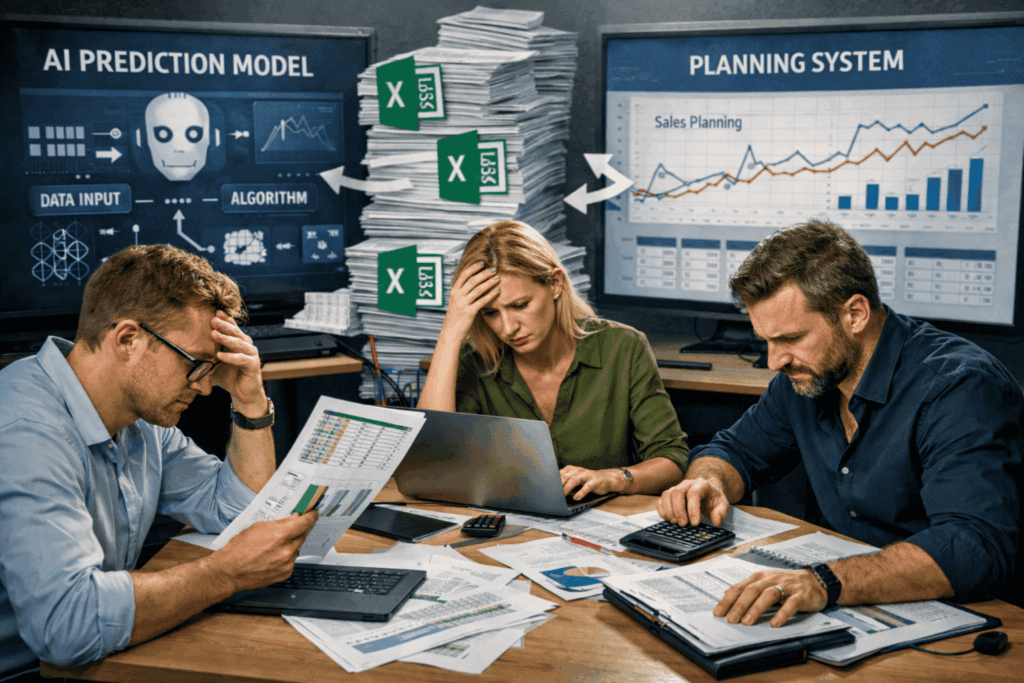

AI is the buzzword of the moment. Everyone wants it, hardly anyone understands it, and even fewer use it correctly. This is especially true for us supply chain managers, or rather, for sales forecasting. Time and again, I see companies spending months fine-tuning AI forecasting models: connecting data sources, optimising parameters, comparing algorithms. The end result is an impressive tool. But it runs completely separate from the actual planning system.

The result? The forecasts from the AI model cannot be integrated into normal workflows; instead, additional steps are always necessary. This is particularly annoying for users of our DISKOVER software: the AI tools run outside the planning system, are not integrated into the simulations, cannot be compared with other methods, and therefore run outside the usual processes.

Instead, they export Excel files, copy numbers back and forth, and enter data manually. A classic weak point. And that doesn’t make the process easier, but more complicated.

But that’s only the first problem.

Secondly, AI is often seen as a panacea. The assumption is that if we invest in AI, it must be used everywhere: for every item, every SKU, every forecast horizon. It sounds logical, but it isn’t.

The reality is different. For stable products with regular sales, classic statistical methods often deliver equally good – sometimes even better – results. With significantly less effort. A widely cited study by Makridakis and colleagues1 showed exactly that: simple statistical methods outperformed complex machine learning models across all forecast horizons. Not because AI is bad, but because it is not the best choice for every application. In our projects on the use of AI forecasts, we also see that ‘only’ in about 25% to 33% of cases does the simulation select AI forecasts as the best method.

Those who ignore this and rely on AI across the board risk the overall result being worse. Or at least not good enough to justify the effort.

Of course, the pressure is there. Management, IT, consultants: everyone is talking about AI. Those who don’t get on board appear backward. I understand that. But technology without process thinking is a waste of resources. And an AI model that no one uses is nothing more than an expensive toy.

So what should be done?

Firstly, consider integration from the outset. Before the first model is trained, it must be clear how the results will flow into the operational process. No isolated solutions, no Excel bridges.

Secondly: differentiate instead of generalise. Use AI where it brings real added value: for complex patterns, many influencing factors, highly sporadic products. Proven methods are sufficient for the rest. Hybrid approaches that combine both worlds often deliver the best results.

Thirdly: compare. Always. If you don’t measure whether AI actually makes better predictions than the previous method, you’re stumbling around in the dark.

Of course, what sounds so simple here is rarely trivial in practice. But those who use AI correctly – in a targeted, integrated and differentiated manner – will come out on top. Those who simply follow the hype will end up with a fancy dashboard but still no better forecasts.

¹ Spyros Makridakis, Evangelos Spiliotis and Vassilios Assimakopoulos, “Statistical and Machine Learning forecasting methods: Concerns and ways forward”, PLOS ONE, 13/3 (2018), e0194889, https://doi.org/10.1371/journal.pone.0194889.