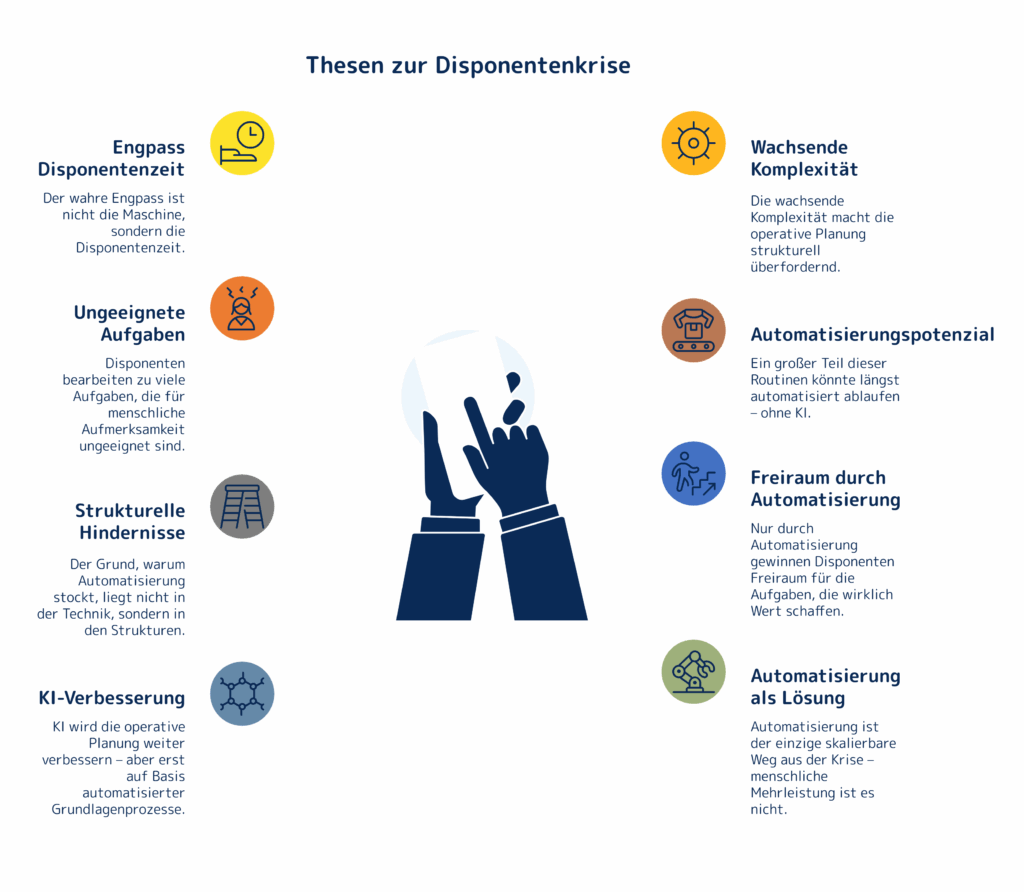

The silent crisis of dispatchers

Eight reasons why automation is the only viable solution

Operational planning is in a structural imbalance: increasing complexity, declining human resources and a working day full of routine tasks that no longer need to be performed by humans. The following column develops the topic along eight clear theses, which together show why automation is not only ‘helpful’ but the only realistic way out of the silent crisis facing dispatchers.

Thesis 1: The real bottleneck in many supply chains is not the machine, but the time available to dispatchers.

Whether a company can deliver, whether inventories rise or fall, and whether throughput times remain stable – all of this depends on operational planning in everyday business. This is precisely where a bottleneck arises that is hardly noticed: dispatchers simply do not have enough time and attention to keep the system stable. This scarce resource increasingly limits the performance of the entire supply chain.

Without sufficient dispatcher time, the operational control capability of a supply chain collapses – long before machines or suppliers reach their limits.

Thesis 2: Growing complexity makes operational planning structurally overwhelming.

Variety, fluctuating demand and uncertain replenishment times increase the management effort much faster than teams can be set up or processes restructured. At the same time, the labour market is becoming tighter. The resulting pressure is systemic – not individual.

Complexity is growing faster than human processing capacity – and without automation, this gap will continue to widen.

Thesis 3: Dispatchers handle too many tasks that are unsuitable for human attention.

Daily order proposals, schedule changes, Excel evaluations, parameter adjustments: these are all repetitive tasks that require little professional judgement – but tie up enormous amounts of time.

The majority of today’s dispatching tasks are not ‘difficult’, but simply unsuitable for large-scale human processing.

Thesis 4: A large part of these routines could have been automated long ago – without AI.

Rule-based scheduling, automatic classification, system-supported parameter optimisation, algorithmic exception control – all of this is state of the art. The necessary automation is widely available and proven. Companies could already systematically map 30–60% of their scheduling work today.

Automation is possible today – it is not a promise for the future, but an untapped standard of the present.

AI will bring additional improvements, but it is not a prerequisite.

Thesis 5: The reason why automation is stalling is not because of technology, but because of structures.

Automation rarely fails due to a lack of tools, but rather due to a lack of framework conditions: unclear regulations, fear of losing control, poorly maintained master data, shadow processes in Excel, low priority of the planning role in management. Operational planning is often undervalued – and therefore does not receive the systemic support it needs.

Automation rarely fails because of software – it fails because of the system in which the software is supposed to work.

Thesis 6: Only through automation can dispatchers gain the freedom to focus on tasks that truly add value.

Less routine work means more time for what people are actually good at: root cause analysis, prioritisation, coordination of critical parts, purchase preparation, collaboration in the S&OP process, continuous improvement of rules and parameters.

Automation does not replace human work – it is a prerequisite for it.

Thesis 7: AI will further improve operational planning – but only on the basis of automated fundamental processes.

AI can detect anomalies, estimate replacement times more accurately, identify atypical requirements and support root cause analysis. But AI needs stable, well-structured data and processes. The groundwork remains: parameterisation, classification, rule creation.

Without automation, there can be no AI – and without structure, there can be no automation.

Thesis 8: Automation is the only scalable way out of the crisis – increased human effort is not.

Companies cannot save operational planning by hiring additional staff – because the staff are not available. Nor can they hope for complexity to decrease – it is not decreasing. The only option that scales is automation. It relieves the burden on dispatchers, stabilises the supply chain and makes organisations less dependent on individual heroic efforts.

Operational planning will not survive through greater effort, but through a new system – and that system is called automation.

Conclusion

Operational planning is tacitly facing a turning point. What used to be compensated for with experience, commitment and manual intervention can no longer be managed today. The solution lies not in more effort, but in a change of perspective:

It is not the dispatchers who need to become faster – the system needs to make smarter decisions.