Dispo parameters: Operational adjustment tool or strategic control instrument?

Disposition parameters are often considered a technical detail in ERP systems – but in reality, they are perhaps the most powerful control tool for your entire supply chain. Setting them incorrectly means wasting potential. Thinking strategically about them gives you a clear competitive advantage.

How much strategy is there in your planning parameters?

In many companies, planning parameters are set to the best of their knowledge and belief – often based on experience, defined once and then hardly questioned for years. What is often overlooked is that these parameters not only have operational implications, but also reflect – or at least should reflect – a company’s entire supply chain strategy.

Disposition parameters determine how a company procures materials, manages inventory and meets customer needs. They therefore determine delivery capability, capital commitment, throughput times and responsiveness – in other words, key supply chain targets. Those who set these parameters ‘on a gut feeling’ or rely on standard values are foregoing enormous potential for strategic control.

Experience is good – simulation is better

Knowing the effect of individual parameters is important, but it is not enough. The key question is:

Would certain overdraft parameter settings have proven effective in the past?

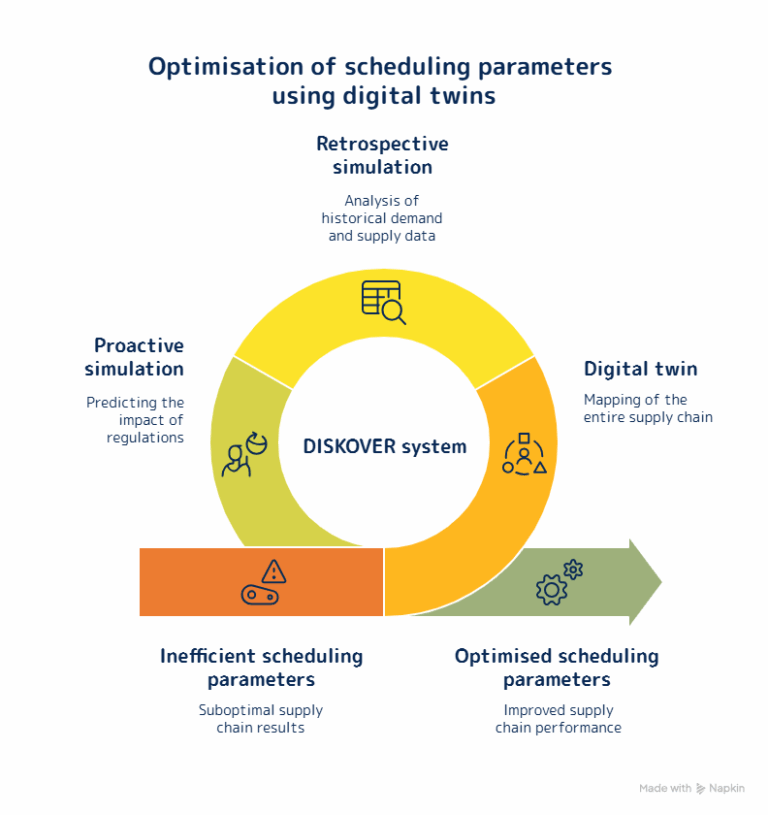

Modern systems for optimising and automatically maintaining scheduling parameters, such as the DISKOVER system developed by our colleagues at SCT GmbH, not only provide a technical tool for mapping scheduling rules, but also map the entire supply chain in a digital twin. This digital twin enables retrospective and proactive simulation of the effects of complex scheduling parameter rules based on real demand and delivery data.

This makes it possible to identify which rules would have led to better results – and which risks certain settings entail.

From strategy to rule – and back again

What is often underestimated is that translating strategic objectives into concrete planning parameters is a demanding task that requires in-depth system knowledge, market understanding, operational experience and extensive experience in designing economical and efficient supply chains.

This is where it is important to work with experienced consultants who have comprehensive supply chain expertise in order to translate a specific target vision for the supply chain into a suitable definition of planning parameters and robust rules and regulations.