Why stocks remain despite everyone wanting to reduce them

On complexity, organisational barriers and the limits of traditional inventory optimisation

– Excess inventory is not a sign of a lack of discipline, but rather a functional element of complex value creation systems.

– Organisational barriers and a lack of methodological tools prevent inventory management projects from being tackled consistently.

-Sustainable inventory management involves fundamental decisions about product portfolios, production logic and risk acceptance – and therefore cannot be limited to the supply chain function, but requires responsibility at management level.

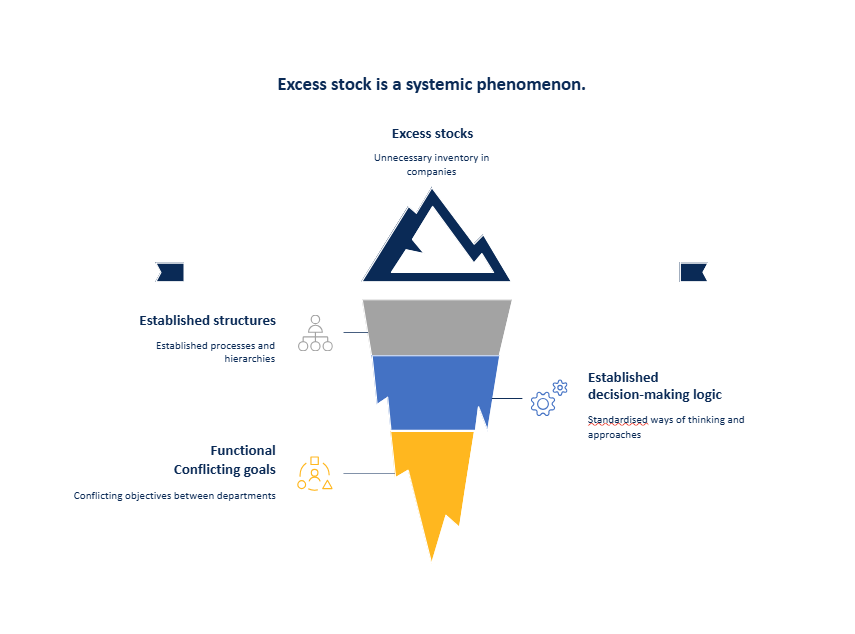

Excess inventory is a systemic phenomenon

Any inventory that is not necessary to ensure delivery readiness is excess inventory. Almost all companies have excess inventory – regardless of industry, size or organisational maturity. Companies are often unaware of the actual extent of this excess inventory. Practical experience from a large number of projects paints a clear picture: according to statistical surveys, which we update regularly, at least 20% of inventory is pure excess inventory in 70% of companies. On average, around 50% of this excess inventory can be reduced within six months without compromising service levels or supply chain stability. The other 50% is difficult to reduce, but it is possible to prevent it from accumulating again after a clean-up measure.

Excess inventory is therefore not a marginal operational phenomenon or an individual failure of specific areas. It arises as a result of established structures, established decision-making logic and functional conflicts of interest. Anyone who wants to reduce inventory must therefore understand why it persists in the system.

Inventories stabilise inefficient systems – and conceal their weaknesses

Inventories act as an organisational lubricant in companies. They ensure that systems remain functional despite inefficient processes, unstable planning or conflicting objectives. Fluctuating demand, unreliable supply chains, inadequate forecasts or a lack of coordination between functions are compensated for by additional inventories.

A certain level of inventory is economically sensible and necessary. A completely inventory-free supply chain would be neither realistic nor economical in most cases. At the same time, nowhere else can structural inefficiencies be identified as reliably as in inventories. High and growing inventories are a very precise indicator that the system is not under control elsewhere.

Inventory management is one of the most economically effective measures

Against this backdrop, inventory management projects are among the most effective measures a company can take. They combine several effects:

-significant release of liquidity,

-sustainable reduction in warehousing and risk costs, typically in the range of 19–30% of inventory value per year,

-improvement in cash flow, earnings quality and crisis resilience.

The payback periods are well under a year. In many cases, inventory management projects are completely self-financing from the liquidity released. The economic benefits are therefore indisputable. The reluctance of many companies to undertake such projects must have other causes.

Complexity makes intuitive inventory optimisation impossible

The real challenge lies in the complexity of modern supply chains. High product variety, volatile markets, multi-stage value chains and globally distributed suppliers have significantly changed the interrelationships between service levels, inventories, batch sizes, throughput times and stability.

These interrelationships can no longer be grasped intuitively. Traditional tools – such as adjusting individual ERP parameters, isolated key figure analyses or Excel calculations – fall short. They look at individual parts, not the overall system. Interventions in one area create side effects in other areas that are not visible in advance.

Under these conditions, neither experience nor ‘common sense’ is sufficient to reduce inventory sustainably.

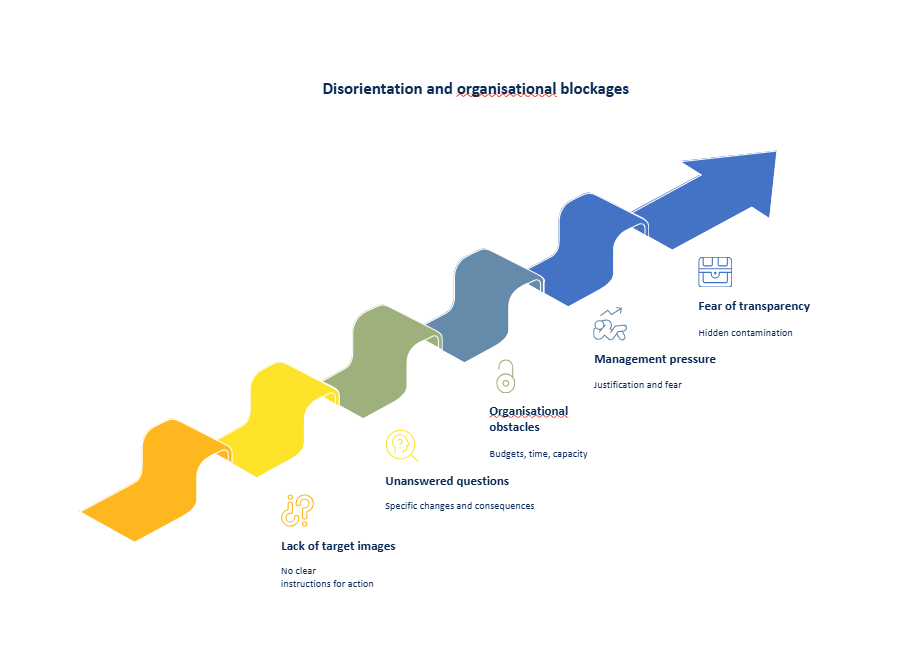

Disorientation and organisational blockages reinforce each other

Many companies recognise the underlying problem. However, what is often lacking are the prerequisites for effective decision-making: a robust target vision, a comprehensible solution and, above all, the certainty that interventions will not cause unintended side effects in the overall system. The central question remains unanswered:

What specific changes do we need to make – and what consequences will this have elsewhere?

At the same time, there are significant blockages at the organisational level. Typical examples include a lack of budget, time and capacity constraints, pressure on middle management to justify their actions, and a fear of transparency and disclosure of accumulated legacy issues. These obstacles are rational and understandable – but they lead to initiatives being postponed, scaled back or avoided altogether.

Methodological disorientation and organisational obstacles reinforce each other. Without a reliable solution, resources cannot be justified. Without organisational support, there is no room to work systematically on solutions. The result is a backlog of action that builds up over years – especially in inventory management.

Simulation as the key to sustainable inventory reduction

Sustainable inventory reduction requires a deep understanding of the dynamic relationships within the overall system. This is precisely where simulation comes in. It maps real supply chains with their rules, restrictions and uncertainties and makes their mechanisms transparent.

Simulation makes it possible to evaluate specific measures and scenarios before they are implemented: Changes in service levels, batch sizes, scheduling logic or portfolio decisions can be quantified in terms of their impact on inventory, stability, throughput times and costs. Assumptions and opinions are replaced by comprehensible cause-and-effect relationships.

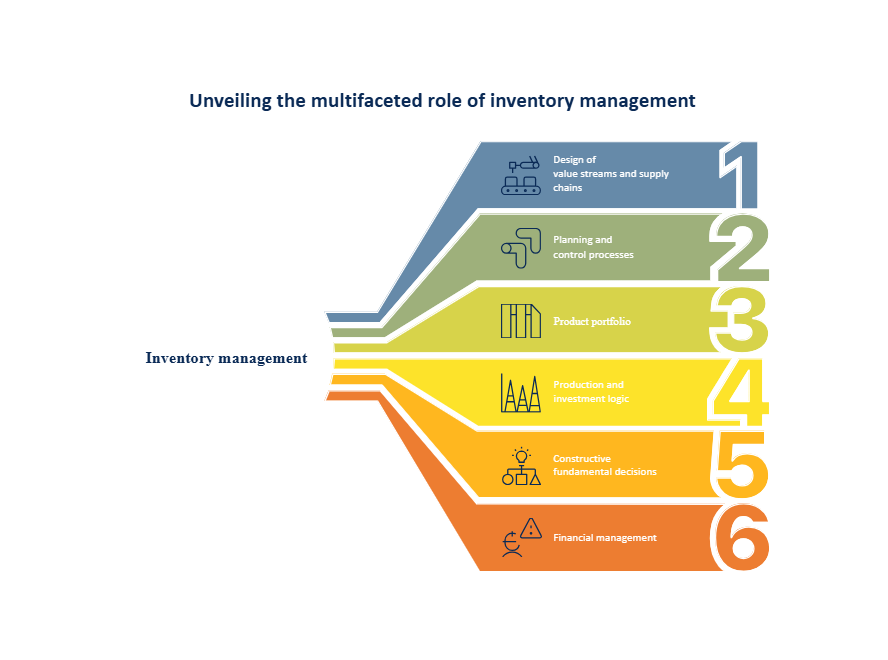

Why inventory management is a task for senior management

Sustainable inventory management is not solely an optimisation project for supply chain management. It simultaneously affects various decision-making areas: the design of value streams and supply chains, planning and control processes, the product portfolio and variant policy of sales and product management, production and investment logic, fundamental design decisions such as modularisation or common parts strategies, and the financial management of working capital and risk.

Inventories are the result of conflicting but rational objectives of different functions. These conflicting objectives cannot be resolved at the departmental level. They require priority decisions about market positioning, risk acceptance, complexity and capital commitment. By definition, such decisions are entrepreneurial management tasks.

Simulations reveal these conflicting goals and force decisions to be made. In doing so, they touch on governance, decision-making rules and responsibilities. Without clear anchoring at the management level, inventory management initiatives often remain limited to treating the symptoms.

Conclusion

Excess inventory does not exist because companies are unaware of its benefits or costs, but because it is a functional element of complex systems. It stabilises inefficient structures, compensates for conflicting goals and keeps value chains functioning even where planning, processes and decision-making logic reach their limits. At the same time, organisational barriers and a lack of methodological tools prevent inventory management projects from being tackled consistently or progressing beyond initial approaches.

In addition, many companies view inventory management too narrowly from a supply chain perspective. In fact, sustainable inventory decisions affect the product portfolio, production and design logic, as well as sales, planning and financial control. The full potential can only be realised if inventory management is not seen as a specialist topic, but as a corporate management task and is anchored accordingly at management level.

FAQs

What exactly is meant by ‘excess inventory’?

Excess inventory is any inventory that is not necessary to ensure the desired delivery readiness. It contributes neither to service quality nor to the stability of the supply chain and ties up unnecessary capital and costs.

Why do almost all companies have excess inventory?

Excess inventory does not arise by chance, but as a systemic result of established structures, planning logic and functional conflicts of interest. It compensates for uncertainties and inefficiencies in the overall system and therefore often remains unnoticed.

Why can excess inventory often be reduced without compromising service levels?

Because a significant portion of the inventory does not contribute to delivery capability. Experience shows that, on average, around 50% of excess inventory can be reduced relatively quickly without negative effects on service or stability.

Why do inventories stabilise inefficient systems?

Inventories act as a buffer against weaknesses in planning, forecasting, processes and coordination. They ensure that value chains continue to function even when structural problems remain unresolved – and at the same time conceal these problems.

If inventory management is so economical, why is it often not implemented?

The main reasons are not a lack of insight, but organisational obstacles (budget, time, capacity, pressure to justify) and a lack of methodological certainty about how to reduce inventories without undesirable side effects.

Why are traditional tools such as ERP parameters or Excel not sufficient?

Because they look at isolated sections. Modern supply chains are highly networked systems in which interventions in one place have effects in another. These systemic effects cannot be reliably mapped with traditional tools.

What is meant by ‘methodological disorientation’?

Many companies know that they should reduce inventories, but they don’t know how. They lack a clear target vision, a consistent solution path and certainty about the consequences that measures will have on the overall system.

What role does simulation play in inventory management?

Simulation makes the dynamic relationships between service levels, inventories, stability and costs transparent. It enables measures to be evaluated before implementation, thereby reducing technical and organisational decision-making risks.

Why is inventory management not just a supply chain management issue?

Sustainable inventory decisions also affect the product portfolio, variant policy, production and investment logic, and fundamental design decisions. A purely operational SCM perspective is therefore inevitably insufficient.

Why can the full potential only be realised at the management level?

Because inventories are the result of conflicting but rational objectives of different functions. These conflicting objectives can only be resolved by overarching priority decisions on risk, complexity and capital commitment – and that is the task of management.