From bartering to bots: supply chain planning as a history of continuous productivity growth

The history of supply chain planning is the history of productivity gains – from the first trade routes to the industrial revolution to AI-powered supply chains. Productivity will remain the guiding principle of successful supply chain strategies in the future. Companies must integrate efficiency, resilience and sustainability equally into their digital supply chains in order to remain competitive.

1. Supply chain planning – the underestimated productivity driver

Supply chain planning (SCP) is the strategic centre of modern value creation. It controls demand, procurement, production and distribution along the entire supply chain – with a clear goal: to increase productivity and use resources efficiently.

While often perceived as a purely operational function, SCP is in fact a key lever of supply chain management. Better forecasting, coordinated processes and the targeted use of digital technologies create sustainable performance.

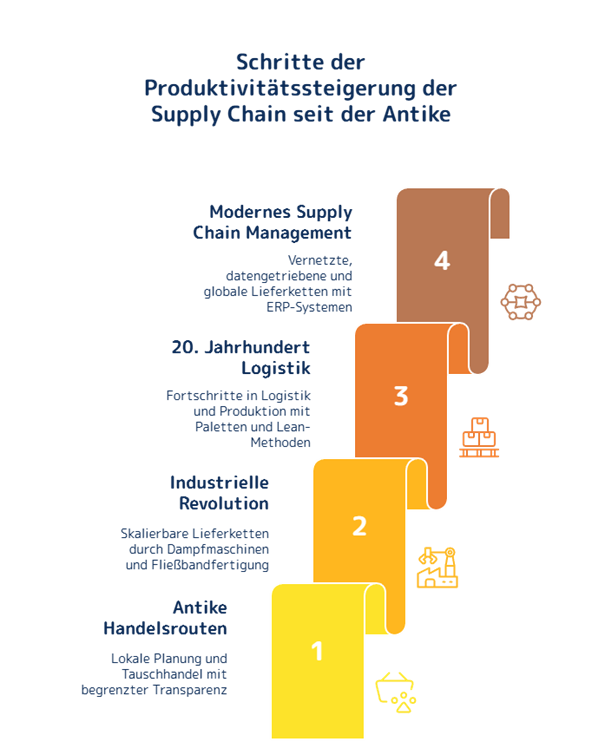

2. Review: Every era brought a leap in efficiency

The development of the supply chain has always reflected technical and organisational advances – and every advance served one goal: greater efficiency at lower costs.

Ancient trade routes such as the Silk Road were based on local planning and barter – with limited transparency and speed.

The Industrial Revolution created scalable supply chains for the first time through steam engines, railways and assembly line production.

The 20th century marked a quantum leap in logistics and production with pallets, containers and lean methods.

With the advent of ERP systems and concepts such as just-in-time, modern supply chain management emerged – networked, data-driven, global.

Whether handwritten ledgers or intelligent algorithms, the purpose remained the same: to accelerate processes, reduce inventories and shorten throughput times.

3. Present: Productivity redefined – data-driven and connected

In today’s digital supply chain, productivity is no longer achieved solely through cost reduction, but through intelligent control, data integration and technological connectivity.

Global uncertainties, volatile markets and rising customer expectations are forcing companies to make their supply chain planning more agile and resilient. Resilience, agility and sustainability are no longer buzzwords, but strategic prerequisites.

Artificial intelligence (AI), machine learning and advanced analytics increase forecast accuracy, identify risks early on and support decision-making. The digital transformation of the supply chain creates transparency and enables continuous improvement in efficiency and service quality.

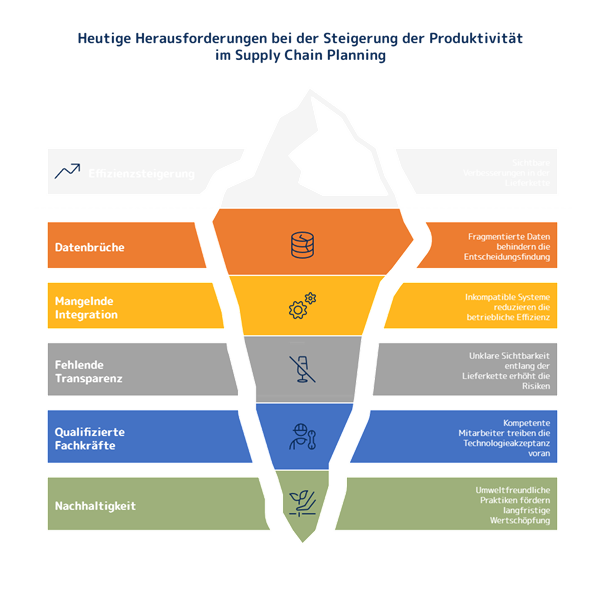

4. Challenges: Productivity needs balance

Increasing efficiency is not a sure-fire success. Priorities must be carefully weighed between cost pressure, delivery reliability and risk protection.

Many companies struggle with data breaches, lack of system integration and lack of transparency along their supply chain. At the same time, the human factor is crucial: productivity is created by technology – but it is sustained by qualified specialists.

Sustainability is also gaining importance. Sustainable supply chains create long-term value, but require investment and structural changes. In future, ecological efficiency and economic productivity must be considered together..

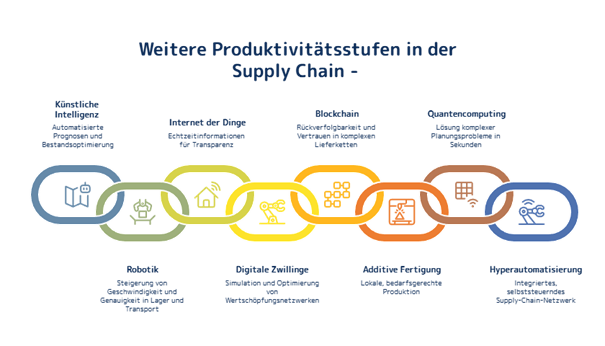

5. Outlook: The next level of productivity in the supply chain

The future of supply chain planning will be shaped by digital technologies that take productivity to a new level:

Artificial intelligence and machine learning: Automated forecasting, dynamic inventory optimisation and more accurate capacity planning.

Robotics and autonomous systems: Increased speed, accuracy and safety in warehousing and transport.

Internet of Things (IoT): Real-time information on inventory, assets and delivery status for maximum transparency.

Digital twins: Simulation and optimisation of entire value networks.

Blockchain: Traceability and trust in complex supply chains.

Additive manufacturing: Local, demand-driven production reduces dependencies and inventory.

Quantum computing: Solving highly complex planning problems in seconds.

Hyperautomation: Linking all systems to form an integrated, self-controlling supply chain network.

At the same time, planning work is changing: it is becoming more strategic, analytical and technology-driven. New skills in data science, AI and process optimisation are becoming the key to success in the next stage of productivity.

6. Conclusion: Productivity remains the guiding principle of the supply chain

From bartering to AI-supported planning, supply chain management has always been a means of increasing productivity. The goal remains the same: to create more value – with less effort, time and risk.

The future belongs to companies that consistently combine technology, data expertise and sustainability. Productivity is not a historical legacy – it is an ongoing mission.

Supply chain planning thus remains the central lever for economic performance in a complex, digital world.

FAQ: Supply chain planning and continuous productivity improvement

Why is supply chain planning considered a driver of productivity improvement?

Because it synchronises processes along the entire value chain, thereby reducing throughput times, inventories and costs. Every advancement in SCP has had the goal of increasing performance with fewer resources.

What historical developments have had a particular impact on productivity in the supply chain?

Significant leaps forward came with industrialisation, standardisation through pallets and containers, the introduction of ERP systems and the lean concept. More recently, digitalisation and AI have been the most important drivers.

Why is productivity understood differently today than in the past?

In the past, productivity mainly meant cost reduction. Today, it also encompasses resilience, sustainability and adaptability – in other words, the ability to operate efficiently while remaining resilient.

What role does artificial intelligence play in modern supply chain planning?

AI enables more accurate forecasts, automates routine decisions and recognises patterns that human planners alone would no longer be able to grasp. It is the key to the next level of productivity.

How is digitalisation changing the understanding of efficiency in the supply chain?

Digital technologies such as IoT, digital twins and blockchain create real-time transparency. This allows processes to be adapted more quickly and bottlenecks to be proactively avoided – an essential step towards sustainable efficiency.

Why does data quality remain a critical success factor for productivity?

Planning is only as good as its data basis. Incomplete or inconsistent data leads to wrong decisions, excess inventory or delivery bottlenecks – and undermines the efficiency gains of modern systems.

What conflicting goals hinder continuous productivity improvement?

Typical conflicts arise between cost reduction, service quality and risk minimisation. In addition, short-term efficiency goals must be reconciled with long-term resilience and sustainability.

How is the role of people in supply chain planning changing?

With increasing automation, humans are becoming designers and analysts. Skilled workers interpret data, manage exceptions and make strategic decisions – supported, not replaced, by technology.

Which technologies will have the greatest impact on productivity in the coming years?

AI, machine learning, robotics, IoT, digital twins, blockchain and additive manufacturing will be the key drivers. Quantum computing and hyperautomation will open up new potential in the long term.

How can companies secure their productivity advantages in the long term?

Through continuous improvement, investment in technology, the establishment of data-driven processes and the development of new skills. Productivity is not a state, but an ongoing process.