Simulation with digital twins as the key to achieving the optimal balance between delivery readiness and inventory

Digital twins can be used to optimally balance delivery readiness and inventory levels in the supply chain. Simulations identify the best scheduling methods, thereby reducing uncertainties in forecasts and inventory levels. This gives companies greater transparency and allows them to exploit specific areas of potential for optimisation. The approach enables measurable improvements in efficiency and delivery reliability. Simulation replaces guesswork with informed, data-based decisions.

The challenge of the modern supply chain lies in striking a precise balance between high delivery readiness and minimal inventory levels. Innovative simulation in a digital twin allows these seemingly contradictory goals to be successfully combined and measurable optimisation successes to be achieved.

The fundamental challenge in supply chain management

Striking a balance between delivery readiness and inventory is one of the most complex tasks in modern supply chain management. Delivery readiness is not a variable that happens to arise at the end of a planning process, but rather a target variable that the entire planning process must be geared towards achieving (best practice rules for efficient planning).

The problem is exacerbated by several factors: most companies do not know their delivery readiness and systematically overestimate it. At the same time, uncertain demand inevitably leads to higher safety stocks, as uncertainties that cannot be eliminated by sales forecasts must be offset by safety stocks.

The situation becomes particularly critical for items with irregular demand, where stocks increase exponentially the higher the required delivery readiness is supposed to be (best practice rules for efficient planning). These relationships between desired delivery readiness and required stock cannot be determined using the standard tools usually available in companies.

The innovative simulation approach

Basic principle of dispositive simulation

The simulation approach is based on a dynamic simulation of the disposition situation over a specific period in the past, typically 12 months. In this process, various forecasting and safety stock methods must compete against each other on the basis of the past performance of each individual item (better to err on the side of accuracy than to guess randomly), as must different scheduling and lot size methods and all other parameters that influence material scheduling.

The simulation system optimises planning in the computer before the parameter settings are implemented in practice – similar to how vehicle bodies are tested and optimised in CAD systems during development (Planning 4.0 for Factory 4.0).

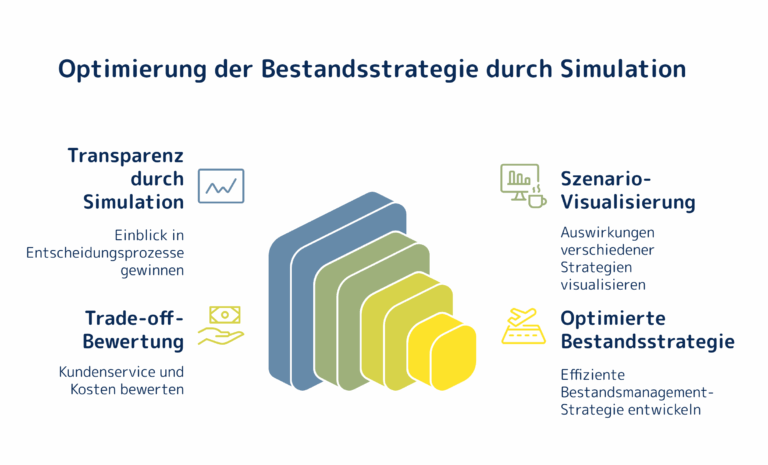

Transparency through simulation instead of black box solutions

A key advantage of modern simulation approaches, as represented in advanced digital twins, is their transparency. Unlike ‘black box’ systems, where users only receive results without insight into the decision-making processes, simulations enable a deep understanding of the interrelationships. Users can understand why certain inventory policies are recommended for different stock levels and what factors influence these decisions.

This transparency is particularly valuable when visualising and evaluating trade-offs between customer service levels and inventory costs. Decision-makers can run through different scenarios and immediately see how changes in inventory strategy affect delivery readiness and capital commitment. This facilitates informed decisions and helps to find the optimal balance between service levels and inventory investments.

Simulation also allows complex interactions between different inventory levels to be visualised, promoting a deeper understanding of the entire supply chain and increasing acceptance of optimised inventory strategies within the organisation.

Multi-echelon inventory optimisation (MEIO) for complex supply chains

Balancing delivery readiness and inventory levels becomes even more challenging when multi-echelon inventory optimisation (MEIO) is the goal. MEIO is an advanced approach that goes beyond the isolated consideration of individual warehouse levels. MEIO solutions recommend optimal inventory levels at every link in the supply chain by optimising the inventory balance across locations. This is particularly important for complex, global supply chains with multiple inventory levels and geographically distributed inventories.

A powerful simulation system must make it possible to consider the effects of inventory decisions on upstream and downstream stages of the supply chain. For example, it must be possible to analyse how increased safety stocks at one location affect inventory requirements at other locations. This holistic view leads to an optimised overall inventory strategy that both ensures delivery readiness and minimises capital commitment.

Especially in times of volatile markets and global uncertainty, MEIO offers a strategic advantage by enabling companies to flexibly adapt their inventory distribution to changing market conditions while optimising the overall performance of the supply chain.

Internal and inter-company supply chains consist of a chain of several locations or storage levels. In order to correctly control the inventory of a single storage level, two essential inventory parameters are generally required: the base inventory and the safety stock. However, multi-level inventory optimisation is an optimisation problem with a large search space that cannot be completely solved using classical mathematical methods.

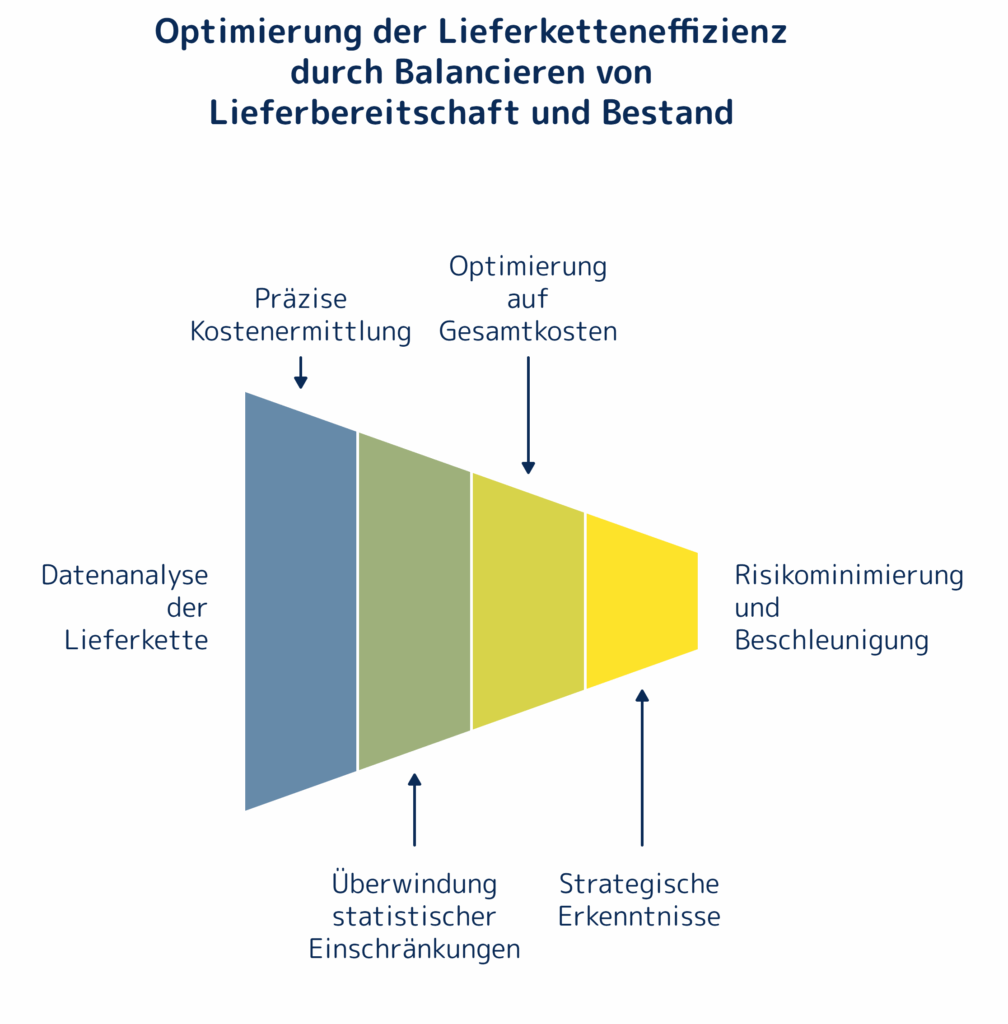

Specific advantages of the simulation approach in modern digital twins

Precise cost calculation

Simulation systems can now be used to reliably calculate which delivery readiness leads to which stock levels for which items. This enables companies to determine what their delivery readiness will cost them and whether they can afford it and want to pay for it, or what they need to invest in stock and thus money in order to remain competitive.

Overcoming statistical limitations

Virtually all classic statistical formulas for forecasting basic requirements and calculating the necessary safety stocks assume a normal distribution of the frequencies of the various demand quantities. In practice, however, this ‘normally distributed demand’ only exists for a few items (better to be wrong than to guess correctly).

AI methods have no difficulty with non-normally distributed demand, but only offer an economic advantage over traditional statistical methods for items with stochastic demand.

Powerful simulation systems therefore have ‘distribution-free’ forecasting and safety stock methods in addition to classic forecasting methods and AI forecasts, which are not confused by a lack of normal distribution.

Optimisation based on total costs instead of forecast accuracy – it’s all about understanding the details

Corresponding simulations show that focusing solely on forecast deviations cannot achieve the lowest total cost of an item or the lowest inventory levels while ensuring the required delivery readiness. The apparent contradiction is easy to explain. In order to reduce total costs or achieve delivery readiness with the lowest possible inventory levels, it is not only the accuracy of the forecast that matters, but also the accuracy of the safety stock, which in turn depends on many planning parameters. It may therefore be more effective to focus directly on achieving delivery readiness with the lowest possible inventory levels or the lowest possible total costs. High forecast accuracy is implicitly achieved in the process.

This challenge cannot be solved without a simulation system.

Delivery readiness with low capital commitment through MEIO

As already mentioned, multi-level inventory optimisation can only be solved with the help of mathematical optimisation methods. Powerful simulation systems provide the necessary functionality.

Fair play with safety stock

The simulation approach makes it possible to avoid incomprehensible or simply arbitrary methods for determining the level of safety stock, which are often based on personal experience, discretion or pure gut feeling (fair play with safety stock).

Risk minimisation and acceleration

Another key advantage of simulation systems – not only when used to balance delivery readiness and inventories – is that they work with clear data and facts. Decisions are based on facts rather than opinions, minimising the risk of wrong decisions. This means that implementation can take place much more quickly in practice and the benefits can be realised faster. This is a key success factor in keeping today’s turbulent supply chains under control, which otherwise change faster than you can keep up.

Conclusion

The simulation approach revolutionises the way companies can optimise the balance between delivery readiness and inventory. By combining big data analytics, precise simulation methods and continuous parameter optimisation, measurable improvements are achieved in both target dimensions.

The technology makes it possible to move from reactive ‘gut feeling’ decisions to proactive, data-driven optimisation strategies. This not only increases operational efficiency, but also sustainably strengthens strategic competitiveness through precise cost calculations and risk minimisation.

In particular, the transparency of the simulation results and the possibility of cross-warehouse optimisation using MEIO methods make this approach an indispensable tool for modern supply chain managers who want to operate successfully in complex, global supply chains.

Note: Big data analytics for Disposition 4.0 using DISKOVER

The DISKOVER SCO tool provides a complete digital twin for the supply chain and value streams, which also offers extensive simulation options. It uses the extensive data sets in the ERP system to determine optimised parameter settings and continuously adjust certain planning parameters (Planning 4.0 for Factory 4.0), for example, thereby enabling an effective balance between delivery readiness and inventory.

The Multi-Echelon Inventory Optimisation (MEIO) process in the DISKOVER software suite optimises the interaction of the individual value-added stages based on state-of-the-art heuristics and metaheuristics from the field of artificial intelligence (AI). This allows inventories to be distributed across the entire supply chain in such a way that the required delivery readiness at the end of the supply chain is achieved with the lowest possible capital commitment across the entire supply chain.

The result: higher delivery reliability with lower inventories across all storage levels – with less planning effort and lower costs.

FAQ

What is Disposition 4.0 and how does it differ from traditional disposition methods?

Disposition 4.0 uses digital technologies, in particular big data analytics and artificial intelligence, to make data-driven and dynamic disposition decisions. In contrast to traditional, often static methods, parameters are continuously optimised and adapted to changing conditions. This enables companies to respond more quickly and accurately to fluctuations in the supply chain.

How does big data analytics help to optimise delivery readiness and inventory?

Big data analytics evaluates large amounts of ERP and supply chain data to identify patterns and correlations. This allows optimal inventory and delivery readiness parameters to be identified and continuously adjusted. This leads to a better balance between low inventory and high delivery capability.

What is a digital twin in supply chain optimisation?

A digital twin virtually maps the real supply chain, enabling real-time simulations and analyses. This allows scenarios to be played out, optimisation potential to be identified and decisions to be tested without risk. This increases the transparency and controllability of complex supply chains.

Simulation methods model the processes and interactions within the supply chain and test various scheduling strategies. They show how changes affect delivery readiness, inventories and costs. This enables companies to make informed decisions and minimise risks.

What advantages does cross-warehouse optimisation with MEIO offer over conventional methods?

MEIO (Multi-Echelon Inventory Optimisation) optimises inventories across all warehouse levels, taking into account dependencies between the levels. This means that inventories are held specifically where they are most important for delivery readiness. This reduces capital commitment and improves adherence to delivery dates.

How does DISKOVER SCO ensure continuous adjustment of planning parameters?

DISKOVER SCO continuously analyses the current data from the ERP system and automatically adjusts the planning parameters. This means that changes in demand or delivery behaviour are taken into account immediately. This increases responsiveness and permanently optimises inventory and delivery readiness.

As a supply chain manager, how can I use the transparency of simulation results?

Simulation results show in detail how different scenarios affect the supply chain. As a supply chain manager, you can use this information to derive targeted measures and understand the impact on costs, inventories and service levels. This facilitates communication and decision-making within the company.

How does optimising the value-added stages affect capital commitment in the supply chain?

Through targeted optimisation of the value-added stages, inventories are only built up where they are necessary for delivery capability. This reduces unnecessary warehousing and lowers the amount of capital tied up. Companies thus benefit from more efficient use of capital.

What role do artificial intelligence and metaheuristics play in inventory optimisation?

Artificial intelligence and metaheuristics analyse complex relationships and calculate optimal inventory strategies even when there are many influencing factors. They make it possible to find significantly better solutions than with classic, rule-based approaches. This effectively optimises both delivery readiness and inventories.

How can I use DISKOVER to improve on-time delivery and costs in my supply chain?

With DISKOVER, you can continuously optimise scheduling parameters and run simulations to analyse the impact on delivery reliability and costs. This allows you to tailor processes to meet delivery deadlines and reduce storage costs. The result is a more efficient and cost-effective supply chain overall.