Plan-driven scheduling is a material requirements planning method used to ensure material availability. In plan-driven scheduling, purchase orders are not triggered on the basis of current stock levels or consumption values (as in consumption-driven scheduling), but on the basis of a requirements plan determined in advance. This is usually based on planned requirements at the finished goods level derived from sales planning (statistical forecasts, customer forecasts, customer delivery schedules, etc.), customer orders or production programmes.

Planned requirements for lower BOM levels (stock levels) are usually derived from statistical forecasts.

At the bill of materials level where the planned requirements are determined, these are balanced with the available stocks to arrive at net requirements. The net requirements are passed on from bill of materials level to bill of materials level and offset against the requirements at each bill of materials level. This is done for all future planned requirements in the planning horizon.

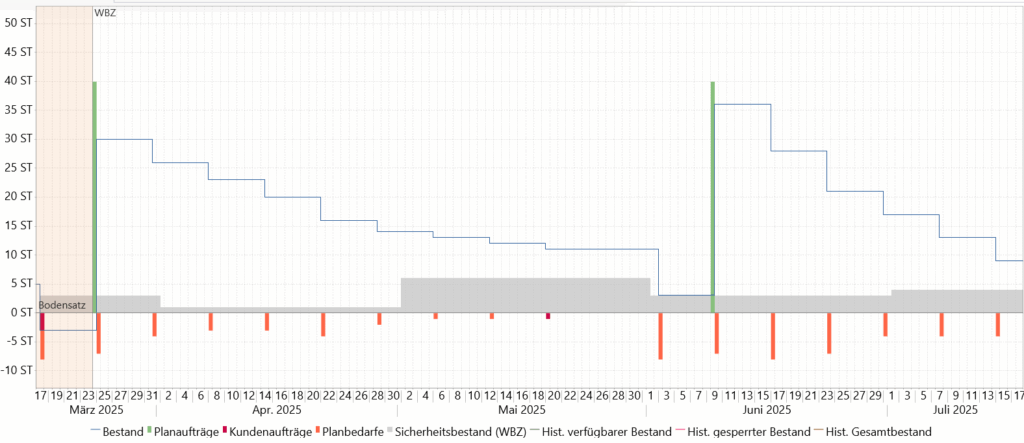

In practical terms, this mechanism means that the future stock history is calculated and determined at each BOM level, and the points in time in the future at which the safety stock (if specified) would be exceeded are identified. A subsequent delivery is scheduled from the underlying BOM level for these points in time. Shifted forward by the replenishment time, this creates a planned requirement at the subordinate BOM level, and so on.

A major advantage of plan-driven MRP is that requirements and stocks are linked across all BOM levels and changes in requirements are passed on downstream in the value stream. For example, a future peak in demand at the finished goods level leads to a corresponding peak in demand at the raw materials level, which is brought forward in time across the replenishment times from BOM level to BOM level.

Our tip:

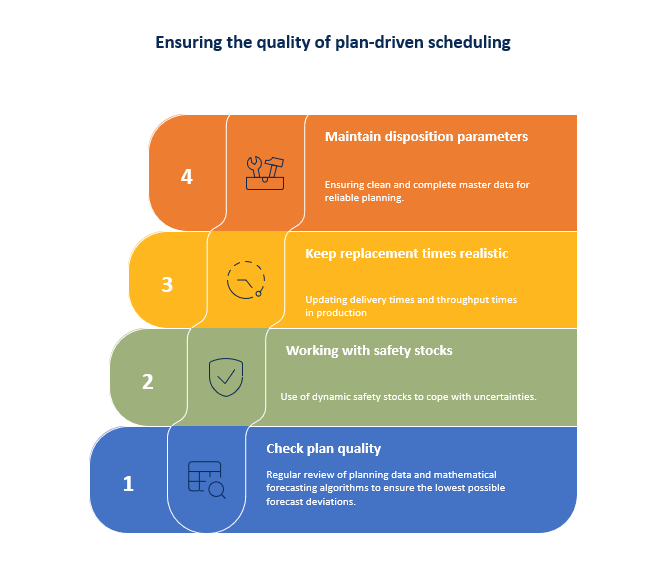

Plan-driven scheduling offers many advantages – such as greater adherence to deadlines and quantities – but it also carries risks, especially if the plan specifications are unreliable or too vague. Therefore, please note the following:

Regularly check the quality of your plans

Plan-driven scheduling is only as good as the planning data. Misjudgements in sales or technical changes to the product can quickly lead to excess stock or missing parts. It is important to calculate forecast values and safety stocks (see point 2) as accurately as possible.

Work with safety stocks

Since ‘planning’ is always subject to statistical uncertainty, statistical safety stocks should always be used. Ideally, no static safety stocks that are assumed to be constant over the planning horizon should be used. Dynamic safety stocks are more suitable, as their level varies over the planning horizon in line with changing planning uncertainty.

Keep lead times and planning dates realistic

Planning lead times, delivery times from suppliers and production throughput times should be checked regularly to ensure they are up to date. Incorrect replenishment times lead to over- or undersupply.

Maintain clear scheduling settings

Incorrect or incomplete master data (e.g. incorrect batch sizes, replenishment times, demand types) can significantly distort demand planning. Clean and ongoing maintenance of the planning parameters is a prerequisite for reliable planning.