The reduction in CO

2

-emissions of companies is now a major topic of discussion and an area of optimization for both manufacturing and retail companies. What can better planning and scheduling mechanisms

to reduce the C

arbon Footprint

contribute?

The question of whether better planning and scheduling mechanisms for reducing CO2-It is very difficult to answer the question of how much a company’s carbon footprint contributes. To ensure that scheduling decisions have a clearly positive influence on the reduction of CO2-consumption, many boundary conditions must be precisely coordinated with this scheduling decision or, conversely, the scheduling decision must take all essential boundary conditions into account.

Smaller lots no longer need to be CO2 production

Ordering in smaller batches, for example, does not necessarily have a negative impact on CO2-emissions, for example, even though there are supposedly more deliveries that generate more CO2-emissions. As long as the delivering truck is still full and does not have to make a detour, order frequency and delivery frequency do not play a significant role in the carbon footprint. With the many scheduling decisions that have to be made every day in most companies, it is not possible to consider the entire process from order initiation to production, storage and delivery for every scheduling decision. Of course, the transportation of goods via environmentally friendly modes of transport contributes to CO2-reduction. However, the decision in favor of a more environmentally friendly mode of transport is typically not a decision made by the planning and scheduling systems. Reducing the number of variants also has a positive effect on CO2-output. However, reducing the number of variants is also not within the control of the planning and control systems. At best, she problems are transparent.

Better material efficiency helps the climate and in the inventory reduction

The extent to which individual functionalities of APS, inventory management or planning systems contribute to reducing the carbon footprint cannot actually be determined. However, it would be wrong to conclude from this that such systems cannot have a positive impact.

The mechanism of action of APS, inventory management or planning systems for CO2-reduction runs to a large extent via the

Improving material efficiency

a parameter that is coming back into focus, especially in the current situation on the global procurement markets. Simply put, anything that reduces the amount of material used in relation to an end product contributes to material efficiency. Please refer to one of the following blog posts on the importance of logistical levers for material efficiency.

Raw, semi-finished and finished materials that have to be disposed of because they are technically obsolete or have exceeded their expiration date, material that shows signs of wear due to long storage or frequent relocation, material that has been damaged or lost in storage – all of this represents a waste of material, the production and delivery of which is CO2 produced and its disposal, if necessary. further CO2-emissions.

The result of the disposition process determines the contribution to climate protection

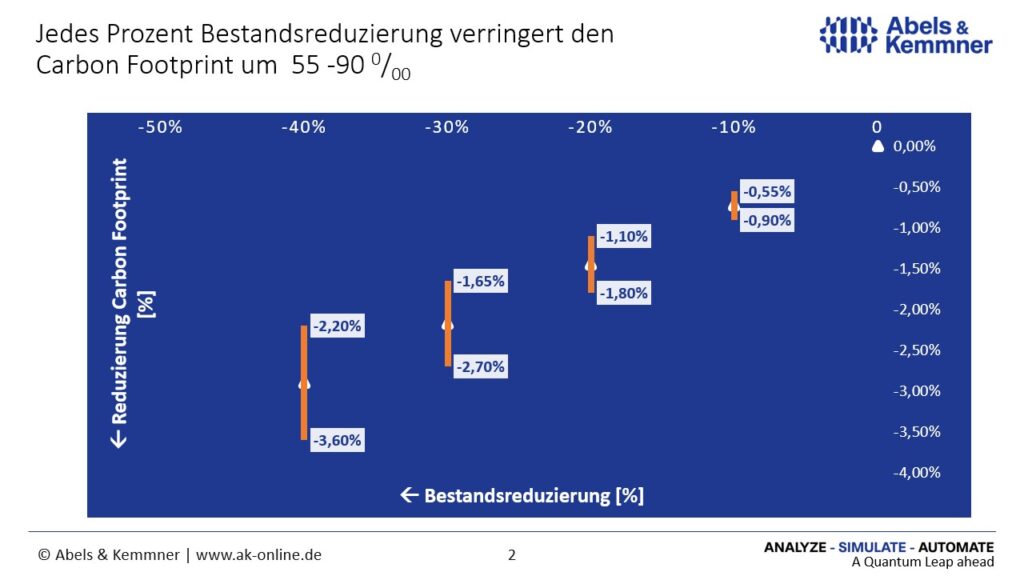

From numerous surveys on inventory costs that we carry out as part of our consulting projects, we know that ageing, wear, loss and breakage change largely in proportion to inventory levels and account for around 5.5 to 9% of inventory costs.

So if it is possible to maintain a constant readiness to deliver and still

a

inventory

reduction in stock

achieve

it can be assumed that ageing, wear, loss and breakage and the associated CO2-use will decrease proportionally. Every one percent reduction in inventory then results in a reduction in the carbon footprint of 55 to 90 per thousand, regardless of how much CO2 the manufacture of the stored products. The prerequisite for this is that the supply readiness required by the market is not impaired, as a reduction in supply readiness compared to the level required by the market also tends to lead to increased CO2-consumption, e.g. due to special trips or partial deliveries.

With regard to the reduction of CO2-consumption, those planning and scheduling mechanisms or APS, inventory management or planning systems that know how to ensure the required delivery readiness with the lowest possible inventory are the most effective: the competition is on!